There’s a scene in the 2000 Joel and Ethan Coen film, “O Brother, Where Art Thou?” that neatly sums up the importance of inventory management and optimization. The film is set in rural Mississippi in the 1930s and follows the antics and adventures of three escaped convicts on the hunt for a hidden treasure. George Clooney’s character (the know-it-all leader of the bumbling band of outlaws) is in a backwoods general store, inquiring about an urgently needed replacement part for his broken-down Model T Ford. The proprietor informs him he can have the part shipped to him in two weeks. Clooney, frustrated, then asks for his preferred brand of pomade, to which the proprietor responds, “I can order it for you, have it in a couple of weeks,” to which Clooney exclaims, “Well, ain’t this place a geographical oddity. Two weeks from everywhere!”

Can you imagine waiting two weeks for a product? In today’s marketplace, it would be unthinkable. How is it that retailers and manufacturers can keep factories humming, store shelves consistently stocked and deliver goods to consumers’ homes in as little as two days? The answer: modern inventory management and optimization techniques.

In this blog, I will explore 3PL inventory management and logistics optimization strategies, including the components of a successful inventory management program, the benefits of partnering with a 3PL, and the role of technology such as logistics optimization software in implementing an effective solution.

What is 3PL Inventory Management?

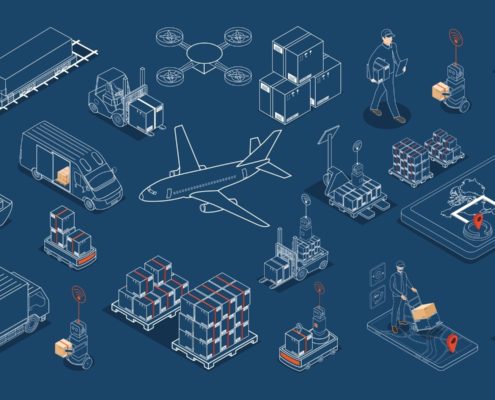

3PL (Third-Party Logistics) Inventory Management is simply the outsourcing of inventory and supply chain operations management to an external service provider. These providers offer a range of services including warehousing, transportation, and order fulfillment that are designed to manage various aspects of a company’s inventory.

Components of 3PL Inventory Management

A third-party logistics company can offer a variety of inventory management services and solutions to support your business model and objectives. These programs can include:

Warehousing and Storage

3PLs can provide warehouse space, either through their own warehouse or through a warehouse provider, for storing a client’s goods. For clients whose products require specialized storage, the 3PL can arrange for climate-controlled facilities (for perishable items such as food, beverages or flowers) and secure facilities (for high value or high-risk goods such as electronics, alcohol, tobacco or other goods frequently targeted by cargo thieves).

Inventory Tracking and Control

Modern warehouses utilize advanced inventory tracking systems that are used to monitor inventory levels, locations of specific goods and the movement of products within the warehouse. The goal of inventory tracking is to maintain optimal stock levels by preventing overstocking or stockouts. As stocks of goods are depleted, the 3PL can manage the replenishment process based on predefined thresholds.

Order Fulfillment Services

3PLs can manage the order fulfillment process on behalf of clients, including picking, kitting and assembly, packing, labeling and shipping. 3PLs can also manage the shipping process from end-to-end, from choosing carriers to preparing shipping labels and tracking shipments to their destination to ensure timely delivery.

Demand Forecasting and Planning

Planning optimal inventory levels to avoid over- or understocking requires inventory management systems that leverage historical data and predictive analytics to create accurate forecasts for demand. 3PLs that provide inventory management solutions can also provide demand planning services to more broadly predict future customer demand for products using customer insights and data related to market trends and economic indicators.

Returns Management

Also known as reverse logistics, returns management has seen a sharp rise in demand. According to a report by Allied Market Research, the global reverse logistics market size was valued at $630.9 billion in 2022, and is projected to reach $947.7 billion by 2032, growing at a CAGR of 4.3% from 2023 to 2032. Ecommerce is a driving force behind this surge in demand, with ecommerce businesses posting a return rate more than three times the return rate for brick-and-mortar retailers.

Transportation Management

Not only do third-party logistics providers manage the transportation function on behalf of clients, they can also improve transportation management through route and load optimization processes. Effective route optimization allows logistics managers to plan optimal routes to reduce transit times, fuel consumption and greenhouse gas emissions. Load optimization ensures that every shipment maximizes the carrying capacity of a given mode of transport, thereby reducing costs and boosting efficiency.

Performance Monitoring and Reporting

3PLs can provide continuous monitoring and analysis of inventory levels and overall logistics operations performance to identify areas for improvement. Reports can be customized for clients based on their strategic goals and objectives.

Benefits of 3PL Inventory Management

3PL inventory management delivers a host of benefits to clients, from efficiency gains and cost reductions to sustainability improvements and more.

Cost Savings

By outsourcing logistics functions to a 3PL partner, 3PL clients can reduce the labor costs, training expenses and other overhead associated with managing inventory in-house. Clients can also benefit from the economies of scale and lower rates that their 3PL partner can negotiate on their behalf. In addition, clients can forgo the investment in costly warehouse facilities, equipment and technology when they partner with a 3PL.

Streamlined Operations

For most clients, inventory management is not a core competency whereas 3PLs that provide inventory management can leverage experienced team members, proven processes and technology to streamline picking, packing, and shipping to accelerate order fulfillment while achieving optimal efficiency. As noted above, demand forecasting and planning play a critical role in ensuring optimal stock levels, which further bolsters operational efficiency and drives customer satisfaction.

Customer Service Enhancements

A 3PL partner can support faster delivery times and accurate order fulfillment which enhances customer service and satisfaction and reduces errors and returns.

Adapting to Market Changes

One of the key benefits of partnering with a 3PL is their ability to help clients adapt to changing market conditions and demand fluctuations with scalable and flexible warehousing and transportation solutions. For clients that experience seasonal demand, or are in a rapid growth phase, the ability to flex up or down in terms of 3PL warehouse space, transportation options and staffing is critical to managing costs and maximizing market opportunities.

Access to Advanced Technology

In addition to seasoned experts, 3PLs can provide state-of-the-art technology, including Warehouse Management Systems (WMS), Transportation Management Systems (TMS), inventory tracking software, automation, and data analytics to manage all inventory and warehouse operations.

Risk Mitigation

Supply chain risk can come in many forms, from supply chain disruptions to complex legal and regulatory environments. A 3PL can implement contingency plans, risk management strategies and regulatory compliance expertise to mitigate and minimize the risks to your operations.

Sustainability

In addition to cost-effective solutions and operational efficiency, a 3PL partner can help clients achieve sustainability goals through load, mode, and route optimization processes that minimize Scope 3 carbon emissions. 3PLs can also utilize energy-efficient warehouses and implement reverse logistics services such as refurbishments and recycling that can further contribute to a more sustainable supply chain.

Strategic Focus

Last but certainly not least, by partnering with a 3PL with warehousing and inventory management expertise, clients can free up valuable time and resources to focus on the core competencies of their business.

Integrating Technology Solutions

3PLs can provide a wealth of technologies to help manage inventory, warehouses and transportation operations. Advanced 3PLs can also provide integration solutions that ensure these systems work together seamlessly.

Transportation Management System (TMS)

Transportation Management Systems are specialized software platforms designed to streamline the planning, execution, and optimization of the transportation of goods. Key features typically include route planning and optimization, carrier management, freight audit and payment, shipment tracking, order management, and reporting and analytics.

Warehouse Management System (WMS)

Warehouse Management Systems are software applications specifically designed to optimize the management of warehouses and distribution centers. Warehouse Management Systems enable the efficient management of inventory, storage, and the movement of good within warehouses or distribution centers. Warehouse management software typically includes inventory management, order fulfillment, receiving and putaway, location management, labor management and reporting and analytics functionality.

Inventory Management System (IMS)

Inventory management software tracks, manages, and facilitates the efficient control of inventory levels, orders, sales, and deliveries. Key functions typically include inventory tracking, order management, stock replenishment, supplier management, barcode and RFID integration, demand forecasting, multi-location management and reporting and analytics.

3PL Inventory Management FAQs

What is 3PL inventory Management?

3PL inventory management refers to the outsourcing of the storage, management and fulfillment of a company’s inventory to a third-party service provider. These services include warehousing, inventory tracking, order processing, and shipping.

What are the benefits of outsourced logistics management?

Companies that partner with a 3PL for inventory management reap benefits including cost savings, enhanced efficiency, improved customer service, access to specialized technology, scalability and the ability focus resources on core competencies of their business.

How do 3PLs track and manage inventory?

Specialized software solutions, including WMS and IMS are used to track inventory in real-time, manage stock levels, and optimize warehouse and distribution center operations. To track products at the individual or SKU level, barcode scanning, RFID, and IoT devices are often utilized. Advanced 3PLs can also provide integration middleware to connect the WMS and IMS to the TMS, ERP and other critical systems.

What is the difference between a 3PL and a 4PL?

Whereas a 3PL may provide services including transportation, warehousing or inventory management, a 4PL acts as an integrator, providing holistic supply chain management services on behalf of its client. This can include managing 3PL services and providing strategic oversight and technology solutions. To learn more about the differences between 3PLs and 4PLs, please click here.

What are the costs associated with 3PL inventory management?

Costs of a 3PL inventory management partnership can vary, depending on the services provided, the volume of inventory, specific storage requirements and transportation needs. Companies can expect that costs will include storage fees, handling fees, shipping costs and technology fees, but this too can vary, so it is important to discuss pricing structures with potential partners.

How does 3PL inventory management impact customer satisfaction and retention?

By enhancing efficiency, accuracy and service quality, 3PL inventory management has a significant positive impact on customer service and retention. Effective 3PL inventory management improves the customer experience in several ways:

- Faster order fulfillment

- Improved order accuracy

- Real-time visibility to inventory data

- Efficient returns management

- Scalability and flexibility

- Enhanced customer service

- Optimal stock levels

- Data-driven insights

- Cost savings that can be passed on to end customers

What factors should I consider when choosing a 3PL provider for inventory management?

Selecting the right 3PL provider for inventory management is a critical decision that can affect your business operations as well as customer satisfaction. Here are some key questions to ask when evaluating a prospective partner:

- Does the 3PL have the appropriate industry knowledge, track record of success, customer service and expertise to support your business objectives and profitability?

- Does the 3PL offer a range of comprehensive solutions that fit your needs? Are their solutions customizable?

- Does the 3PL use advanced technology including WMS, TMS, IMS and integration software?

- Does the 3PL’s geographic coverage and reach align with your key markets?

- Can the 3PL provide scalable and flexible solutions to help you adapt to changes in your supply chain needs and objectives?

- Is the cost structure transparent? How do the costs compare to competing 3PL providers? What is the overall value of the partnership?

- Do the providers’ solutions support your sustainability objectives?

This is just a sampling of the factors to consider when selecting a 3PL inventory management partner. As the demands of modern supply chains continue to evolve, businesses that embrace 3PL inventory management can achieve greater operational efficiency, adapt to market changes with agility, and maintain a competitive edge in delivering exceptional service to their customers. To learn more, please contact Sheer Logistics today.

Whether you need full logistics management, carrier sourcing, or help with any part of the logistics process, Sheer Logistics delivers industry experts and cutting-edge technology that deliver bottom-line results.