Logistics optimization is the process of maximizing efficiency and minimizing costs in the supply chain and is a critical part of 4PL/Managed Transportation Services partnerships. As Chief Supply Chain Officer at Sheer Logistics, and in prior logistics industry roles, I have been personally involved in hundreds of supply chain optimization engagements and initiatives. In this post, I’ll explore the importance of optimization, discuss the latest in optimization technology, the role of data and analytics, future trends in optimization and more. With this post, I hope you will find some information about optimization that sparks actionable ideas for optimizing your supply chain.

What is Logistics Optimization?

The ultimate goal of logistics optimization is to streamline supply chain operations to increase efficiency, reduce costs, improve customer satisfaction and boost profitable growth. This can be accomplished in a number of ways and involves the analysis of various parts of your supply chain, including transportation, warehousing and distribution centers (both in terms of site selection and operations), inventory management, order fulfillment, and more.

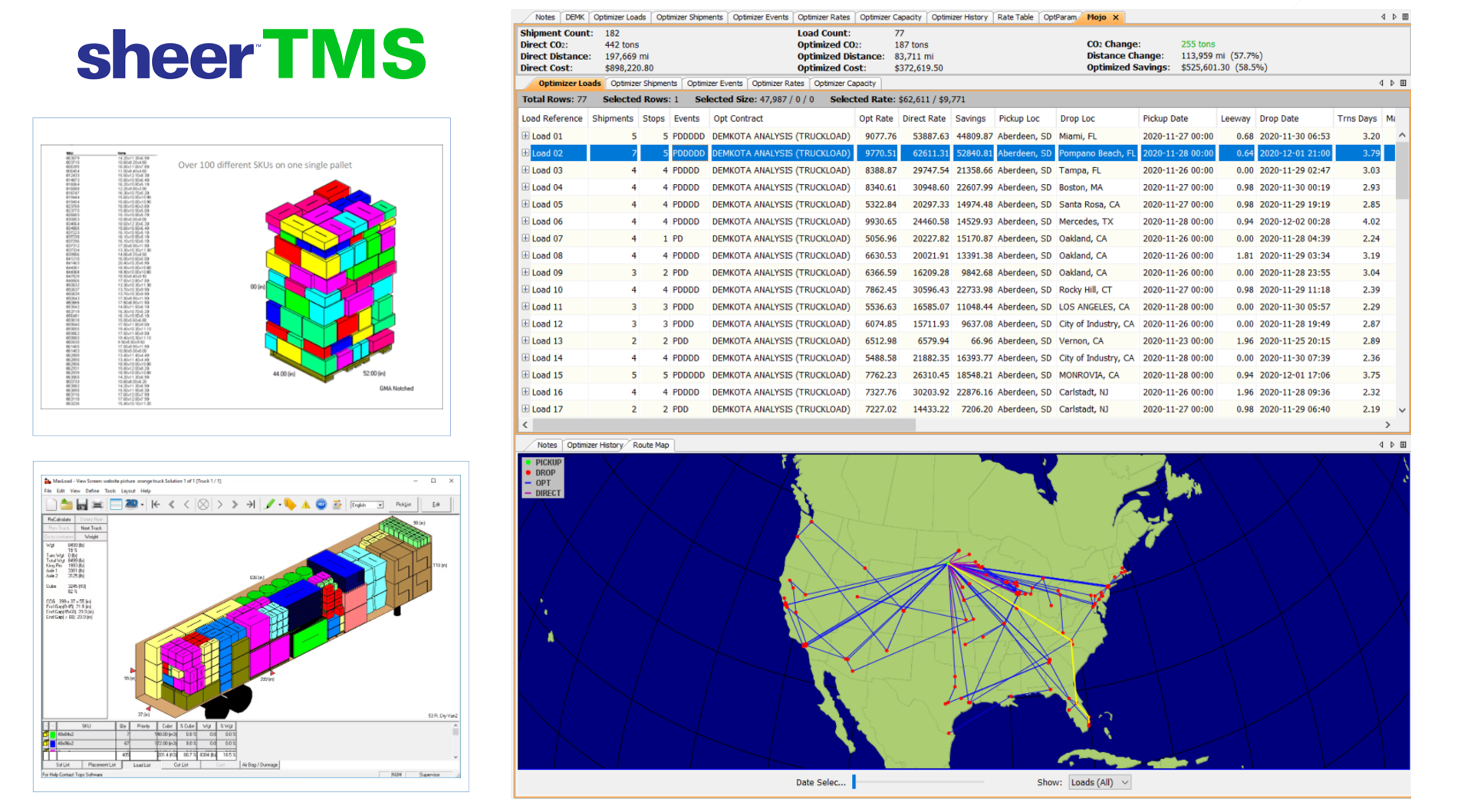

Sheer’s best-in-class optimization engine can be run automatically on a monthly, weekly, or even daily basis.

The Importance of Logistics Optimization

Optimization is critical to maintaining competitiveness in a dynamic global market. As business leaders increasingly view logistics and supply chain as a strategic pillar in their business, rather than merely a cost center, optimization has emerged as an area of central focus. When executed properly, optimization can be a strategic advantage that helps businesses become more competitive and profitable. However, many business leaders lack the internal technical and people resources to develop and execute optimization strategies. 4PL/Managed Transportation Service providers can play a critical role in providing the expertise, technology, and strategic focus required to successfully implement optimization initiatives.

7 Efficient Strategies for Logistics Optimization

Optimization analyzes almost every aspect of the supply chain to identify areas for improvement and efficiency gains. Here are some of the most commonly used supply chain network optimization strategies:

- Route Optimization: Finding and using the most effective route from point A to point B for individual shipments is deceptively simple. A route optimization analysis will assess factors beyond the mileage to consider cost, time, traffic patterns, delivery windows, vehicle capacity, and more. A 4PL/Managed Transportation provider will utilize route planning software to create optimized routes specific to your supply chain needs and goals.

- Mode Optimization: Mode optimization helps shippers determine which transportation mode is best for their shipments based on factors including cost, delivery times and reliability. Shippers are increasingly including sustainability concerns in their approach to mode optimization, allowing them to consider the environmental impact of a shipment in their optimization analysis.

- Load or Container Optimization: Also, known as “cubing” or “cubing out” the space in a trailer or shipping container, load or container optimization ensures that the available space in the selected vehicle is being maximized to the greatest extent possible while considering other parameters such as maximum weight and commodity compatibility.

- Rate Optimization: Rate optimization is a strategic process designed to minimize transportation costs while maintaining desired levels of service. This often includes rate negotiation, carrier selection, and rate benchmarking.

- Carrier Optimization: Carrier selection takes a strategic approach to managing carrier relationships based on factors such as service levels, capacity, coverage, equipment, and pricing.

- Warehouse and Distribution Center Optimization: Optimizing warehouses and distribution centers refers to both site selection, that is, where the facilities are located, and optimizing internal operations. Site selection takes into account the proximity of the facility to target markets and end customers, proximity to source of supply and manufacturing, access to transportation infrastructure such as highways, railroads, ports and airports, labor availability, real estate costs, state and local taxes, transportation costs, regulatory considerations, and plans for future growth.

- Inventory Optimization: As many shippers experienced both during and after the COVID-19 pandemic, managing inventory levels can be a daunting task. Inventory optimization involves demand forecasting, inventory optimization software tools, automated inventory storage and retrieval, inventory analysis techniques, inventory segmentation, Just-in-time (JIT) inventory practices and other approaches to ensure the right amount of products are available at the right place and the right time to meet customer demand.

Integrate the Latest Technologies

As supply chain digitalization continues, integrating the latest technology solutions is key to supply chain optimization. Advanced 4PL/Managed Transportation providers offer Integration Platform as a Service (IPaaS) or integration middleware, to quickly and easily integrate disparate systems such as Enterprise Resource Planning systems (ERP), Transportation Management Systems (TMS), Warehouse Management Systems (WMS) and other tools to drive your optimization initiatives forward:

- Optimization Systems: There are a variety of transportation modeling and optimization tools available to shippers, such as MercuryGate Mojo, which is offered as a standalone tool or as a module within the MercuryGate TMS, that automate the optimization process.

- AI and ML: Optimization tools are increasingly leveraging powerful AI and ML technology to deliver accurate, actionable insights more quickly than ever before.

- Predictive and Prescriptive Analytics: Predictive analytics utilizes logistics data, algorithms, and machine learning to forecast future trends or occurrences by analyzing patterns in historical data. Prescriptive analytics takes predictive analytics a step further by offering actionable suggestions that supply chain leaders can act upon, leveraging specified inputs.

- Digital Twins: Digital twin technology supports both predictive and prescriptive analytics models by employing virtual representations of systems, logistics processes, and physical entities to mirror their real-world counterparts in real-time. This technology empowers supply chain management professionals to explore countless hypothetical scenarios and predict potential outcomes with precision.

Set Effective Performance Metrics

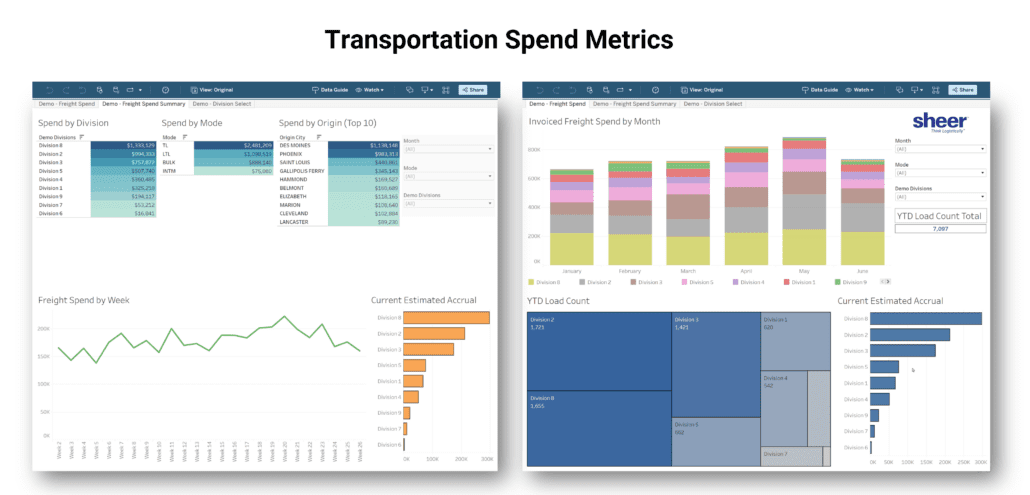

Setting key performance indicators (KPIs) is critical for logistics network optimization as it enables organizations to define and measure success, identify areas for improvement, ensure alignment with overall business objectives, and establish accountability. This fosters a culture of continuous improvement within the organization and promotes communication and transparency across the organization.

Implement Customer Feedback

Customer feedback can be a valuable source of insights and guidance for your logistics management and optimization efforts. Systematically collecting customer feedback allows shippers to track Net Promoter Score (NPS), a measure of customer experience and satisfaction, loyalty, and willingness to recommend your company to other potential customers.

Customer feedback can also provide insights into root causes of logistics-related issues that drive customer dissatisfaction. By proactively identifying recurring problems and trends, you can address the underlying issues and strengthen your customer relationships.

Build Strong Supplier and Partner Relationships

Committing to logistics optimization can also help shippers build stronger relationships with suppliers and partners. Optimization contributes to improved supply chain performance through improved visibility and transparency, allowing suppliers and partners to collaborate more effectively. Optimization empowers shippers to be more proactive in identifying and addressing supply chain issues that could impact partners and suppliers, helping preserve these relationships through potential disruptions. Logistics optimization also drives deeper collaboration that can foster mutual trust and alignment of interests and goals among supply chain stakeholders.

Future Trends in Logistics Optimization

As logistics technology continues to advance, there are several areas of innovation that bear watching for shippers. As I discussed above, Artificial Intelligence and Machine Learning will play an increasing role in logistics optimization. As recent developments in the fields of AI and ML have shown, this technology is rapidly advancing, and its ultimate impact is unpredictable. What is certain is that logistics providers will continue to find new applications for AI and ML which drive efficiency, reduce logistics costs and empower shippers to make timely and informed business decisions through automation, advanced analytics, and real-time optimization.

The proliferation of Internet of Things (IoT) and sensor technology is already providing greater supply chain visibility and real-time tracking of assets, inventory, and even individual shipments. Taken in concert with AI and ML-driven advanced analytics, IoT-enabled devices will facilitate data collection, monitoring, and analysis that inform optimization data-driven decision-making.

As noted above, shippers will increasingly add sustainability goals to their optimization checklist. Just as shippers have sought to optimize every aspect of their transportation and logistics operations, optimizing shipping activities to take GHG emissions into account will become more commonplace, particularly as government regulations are put in place that require emissions reporting.

Key Takeaways

Logistics optimization is essential for shippers aiming to maximize efficiency, secure cost reduction, and maintain competitiveness in the global market. It’s a transformative process that seeks to shift supply chain and logistics from a mere cost center to a strategic advantage, pivotal for driving profitability and growth. Collaborating with 4PL/Managed Transportation Service providers can provide access to expertise, technology, and strategic focus necessary for successful optimization initiatives. Working with a 4PL/Managed Transportation provider, shippers gain access to a range of efficient strategies, from route and mode optimization to load, rate, carrier, warehouse, distribution center, and inventory optimization, each tailored to specific supply chain needs and objectives.

Integration of cutting-edge technologies like optimization systems, AI, ML, predictive and prescriptive analytics, and digital twins is crucial for driving actionable insights and achieving optimization goals. Leveraging data analytics and forecasting allows shippers to make informed decisions, anticipate demand, and set effective performance metrics, fostering continuous improvement and innovation in logistics operations. By incorporating customer feedback into optimization efforts and optimizing costs, shippers can strengthen relationships with suppliers and partners, enhancing collaboration, performance, and visibility.

Looking ahead, future trends in optimization, such as AI, ML, IoT, sensor technology, and sustainability, will shape the landscape, empowering shippers to drive efficiency, increase cost-effectiveness, and make informed decisions in an evolving market environment. To learn more, please contact us.

Whether you need full logistics management, carrier sourcing, or help with any part of the logistics process, Sheer Logistics delivers industry experts and cutting-edge technology that deliver bottom-line results.