Fourth Party Logistics providers, or 4PLs, go beyond providing a single logistics function, often managing and integrating a shipper’s entire supply chain and logistics operation under one service provider. This can include managing multiple 3PLs if necessary. In this post, I’ll discuss how 4PLs and 3PLs differ, the main characteristics of 4PLs, advantages of the 4PL model, what shippers can expect when implementing the 4PL model, and how to select a 4PL partner.

Key Takeaways

What is a 4PL?

A 4PL is a logistics service provider that oversees and manages the entire supply chain in behalf of a company. This can often include managing multiple third-party logistics providers (3PLs). A 4PL acts as a strategic partner to its clients, with an overarching goal of optimizing the supply chain, creating efficiencies, reducing costs, enhancing visibility and creating an environment in which business leaders have access to the data they need to make empowered business decisions and achieve their objectives.

What are the Differences Between 3PL and 4PL Logistics?

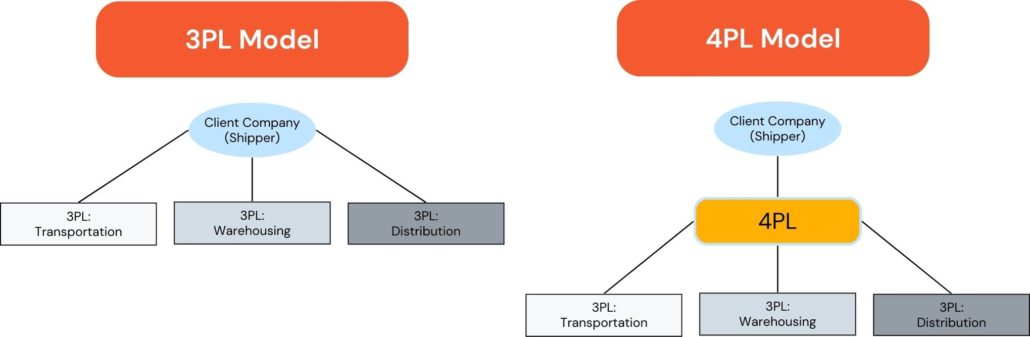

4PL providers go beyond providing a single logistics function, often managing and integrating a shipper’s entire supply chain and logistics operations under one service provider. This can include managing multiple 3PLs if necessary. For example: large shippers often utilize multiple 3PL providers to ensure they have access to the truck capacity they need to move their shipments and to do so at competitive rates and the desired level of service. Managing multiple 3PLs can be a cumbersome task, requiring the continued investment in large internal teams and logistics technology. 4PLs can manage multiple 3PLs on behalf of the shipper. These 3PLs can include not only transportation-focused 3PLs but also those that specialize in warehousing, distribution, or other specific logistics functions.

Due the complexity of managing a supply chain with many players, and many other reasons we will explore below, large shippers often partner with 4PLs (this is often to referred to as “outsourcing”). Increasingly, small- to medium-sized shippers are embracing 4PLs and/or Managed Transportation Services models as well, as TMS and integration technology become more cost effective and attainable.

In order to understand the world of Fourth-Party Logistics, or 4PLs, let’s take a step back and look at Third-Party Logistics (3PLs). When it comes to over the road transportation, at its most basic, there are three parties involved in getting a shipment from origin to destination: (1) the shipper, that is, the manufacturer or owner of the goods to be transported; (2) the carrier, that is, the trucking company hauling the goods; and (3) the 3PL, sometimes referred to as a broker, who acts as a middleman between the shipper and carrier. This is a very simplified definition, as a trucking company (i.e. an asset-based carrier) may also have a 3PL or freight brokerage arm. 3PL can also refer to a warehouse/distribution provider, freight consolidation or other services. Freight forwarders are sometimes considered 3PLs. While it can be confusing, at its core, 3PL can refer to any third-party that is providing logistics and/or transportation services that is not the shipper or the carrier.

Understanding the Different Levels of Logistics Services

As the logistics services market has evolved, several logistics models have been developed to meet the needs of shippers at a variety of levels of complexity. For more definitions, please visit the CSCMP website.

First Party Logistics

First party logistics, or 1PL, refers to companies that handle all of their logistics, warehousing, and transportation functions in-house. 1PLs may own assets (i.e. a trucking fleet) or may simply manage their transportation internally by contracting directly with asset-based carriers.

Second Party Logistics

The term 2PL is sometimes used to refer to asset-based carriers that provide the transportation function to shippers. Carriers that offer freight forwarding are sometimes referred to as 2PLs.

Third Party Logistics

Third-party logistics providers, or 3PLs, refers to logistics companies such as transportation brokers, warehouse/distribution provider, freight consolidator or other entity that acts as an intermediary on behalf of the shipper. In this model, among other functions, the 3PL provides procurement services, leveraging its network of carriers to identify the right transportation solution. The 3PL market has seen strong growth in recent years and is expected to grow 7.6% CAGR to $2.14B by 2032.

Fourth Party Logistics

Also referred to as a 4PL, Lead Logistics Provider (LLP) or Managed Transportation provider, a 4PL company goes beyond providing a single logistics function, often managing and integrating a shipper’s entire supply chain network. This can include managing multiple 3PL partners if necessary.

Fifth Party Logistics

5PL, a relatively new concept, is somewhat loosely defined. It can refer to a logistics services company that manages 3PLs and 4PLs on behalf of a shipper. 5PL can sometimes refer to logistics companies that manage the entire supply chain on behalf of a shipper and seek to find efficiencies and synergies between the supply chains of common customers.

Main Characteristics of 4PL Logistics

4PLs offer a wide variety of logistics and supply chain solutions. Here are a few of the core competencies of an established 4PL.

Day-To-Day Supply Chain Management

The 4PL serves as single point of contact overseeing the entire supply chain, with dedicated resources that act as an extension of the shipper’s team. As noted above, one of the defining characteristics of the 4PL model is its scope. Unlike 3PLs, which focus on a specific service, 4PLs take a holistic and comprehensive view of a shipper’s entire supply chain operations, orchestrating a supply chain strategy that can include the sourcing and delivery of raw materials, warehouse management, inventory levels and management, order fulfillment, and the shipping of goods to end consumers.

Technology and Integration

Technology is core to the 4PL offering. 4PLs typically offer Transportation Management System (TMS) and integration technology which create a centralized platform for visibility and monitoring often referred to as a Control Tower. Integrating disparate systems, vendors and service providers is core to the 4PL value proposition. This requires integration technology, to seamlessly weave together Enterprise Resource Planning systems (ERP), Transportation Management Systems (TMS), Warehouse Management Systems (WMS), Real-Time Transportation Visibility Platforms (RTTVP), Fuel Programs, Rating Engines, and other point solutions. Without effective integration, the 4PL model simply does not function.

Communication and Relationships

In the 4PL model, technology and skilled logistics professionals go hand in hand. Despite dizzying advancements in logistics technology, including AI tools, effective 4PLs run on people power. There is simply no substitute for decades of experience in the logistics industry, and the 4PL’s ability to seamlessly and proactively communicate strategies, challenges and opportunities is a hallmark of a successful partnership. 4PLs often draw talent from the ranks of the shipper, tech, 3PL and consulting communities. Some of the most effective 4PL leaders have experience in multiple roles, allowing them to see the supply chain through the eyes of the shipper, or to leverage insights gleaned from dozens of engagements as a consultant. Experienced logistics pros also bring key relationships to the table that can benefit shippers as they develop a customized strategic approach.

Cost Reduction

4PLs drive cost reductions in a variety of ways, including direct freight savings, efficiency gains, service improvements, reduced need for hiring, administrative costs related to accounting and freight pay and audit, and more. While cost savings are an important goal, it is not the only goal of a 4PL partnership. As we will explore below, visibility and access to data, risk mitigation, agility and other benefits are equally important.

Visibility, Business Intelligence and Analytics

Integrating disparate systems also enables one of the key benefits of the 4PL model: pulling data from across the supply chain into a single location and making it available for analysis. 4PL providers leverage powerful analytics technology to harness the huge volumes of supply chain data they capture and to help shippers make sense of it all by deriving key insights and actionable intelligence that drive timely decision making.

Strategic Planning

Broadly speaking, whereas the world of 3PLs, primarily brokerages, can be considered largely tactical, 4PLs are focused on solving challenges at the strategic level, addressing how a shippers’ logistics and supply chain fits into and helps drive overall business strategy and goals. When shippers are growing quickly, expanding into new markets, looking to build new facilities or relocate their manufacturing, fulfillment centers warehousing operations, or faced with other strategic decisions, such as supply chain design and logistics optimization and a myriad of other functions that go beyond getting a shipment from point A to B, 4PLs provide valuable support and expertise.

Customized Solutions

This strategic focus means that the solutions that 4PLs offer are tailor-made for their shipper clients. Because every supply chain and its challenges are different, so too are the customized solutions that 4PLs develop to help shippers achieve their goals.

Agility, Flexibility and Scalability

We’ve discussed how unifying data from across the supply chain can drive agile decision making, but 4PLs enable shippers to be agile in other ways as well. By serving as an extension of the shipper’s team, 4PLs enable flexibility and scalability to empower shippers to quickly react to changing market demands. In practical terms, this means that as shippers grow, they can support that growth with support from their 4PL rather than expanding the size of their internal teams.

Advantages of 4PL Supply Chain Management

4PLs deliver many benefits to shippers, including:

- Proven freight savings

- Efficiency gains

- Service improvements

- Enhanced visibility and control

- Access to logistics expertise

- Risk mitigation

- Improved business intelligence and more.

A survey of shippers who utilize 4PL services conducted by ARC Advisory Group, DC Velocity and Eye For Transport (now part of Reuters) found that 68% of respondents save 3-5% or more on freight costs, with 32% of respondents saving 12% or more. The same study showed that 45.9% of respondents experienced service improvements of 5% or more, with the majority seeing improvements in the 5-10% range.

How Does the 4PL Business Model Work?

If you are considering a 4PL partnership, here is an overview of the process from initial consultation to go-live and beyond.

1. Needs Analysis

While much of this will have been addressed during the RFP process, once you have selected a 4PL partner, you can expect them to take a deep dive into your company’s specific supply chain goals, needs and challenges. This analysis will include a review of your current supply chain, including infrastructure, operations, processes and procedures, technology, risks, gaps and more and how they relate to your overall goals and objectives. The goal of the analysis is to inform the next phase of the process, strategic planning.

2. Strategic Planning

In this phase, you will collaborate closely with the 4PL’s solutions team to develop a customized supply chain strategy that addresses the challenges, obstacles and goals identified in the analysis phase. In this phase, you are essentially developing the roadmap for your supply chain. The strategic plan will address all aspects of your supply chain, including people, processes, technology and infrastructure.

3. Integration

As noted above, this is a key step in the implementation process, in which your various logistics providers are all brought under the singular umbrella of the 4PL. The timeline for this phase is highly dependent on the complexity of your supply chain and the systems and partners that need to be integrated.

4. Establish Key Performance Indicators (KPIs)

In this phase, you will collaborate with the 4PL to identify and define the KPIs that align with your goals and objectives that will be used to measure performance.

5. Go-Live

Once the preceding steps have been completed, the 4PL solutions go live and moves into a day-to-day management and continuous improvement phase.

6. Management and Continuous Improvement

The 4PL provider will take on the execution of day-to-day tasks, proactively communicating to keep you apprised of performance to the established goal metrics as well as challenges and opportunities. The provider will leverage data and analytics to drive continuous improvement.

4PL for Different Industries

4PL services have wide applications, offering many ways to support the unique goals of companies in diverse industries.

Retail and Ecommerce

Retailers and ecommerce companies partner with 4PLs to streamline their supply chains, integrating everything from upstream suppliers to final mile delivery providers and reverse logistics to manage the stream of returned orders. Retailers with a global, multichannel presence can leverage 4PL services to optimize their transportation networks, reduce costs, provide fulfillment services, improve delivery times and increase customer satisfaction. Sheer Logistics implemented a 4PL solution on behalf of a leading global manufacturer and distributor of beauty and personal care products, coordinating logistics management and processes across three distinct sales channels (including retail, wholesale and ecommerce distribution centers) spanning 150 countries and a portfolio of 36 brands.

Grocery, Food and Beverage

Grocers and food and beverage producers leverage 4PLs to ensure the safe and timely delivery of perishable products. The 4PL orchestrates the transportation and on-time delivery of products, helping shippers mitigate or avoid chargebacks from their grocery customers related to deliveries that are not on time and delivered in full. 4PLs can also support the rapid growth of food producers. Sheer Logistics helped a protein processor that was experiencing rapid sales growth take increased control of their supply chain through a Managed Transportation/4PL partnership. Sheer identified $675,000 in initial transportation costs savings, and over the first two years of the engagement, the client saw gross savings of $2.1MM.

Cold Chain

Cold chain logistics can be particularly challenging, and once again, 4PLs can play a critical role in mitigating risk and driving customer success. The products that move through the cold chain are highly perishable, and appropriate temperatures must be strictly maintained throughout the entire supply chain. Accomplishing this requires specialized equipment, facilities and expertise to ensure freshness and to avoid losses due to spoilage. Sheer Logistics supported a leading processor of fresh and frozen turkey, beef, chicken and pork with operations spanning across 10 warehouses and two manufacturing plants, helping them save money, increase efficiency and improve overall performance through the speedy implementation of a 4PL solution and TMS.

Chemicals and Specialty Materials

Safely transporting chemicals and other specialty materials requires compliance with myriad safety and regulatory standards. A 4PL can help shippers navigate this complexity, manage the specialized carriers required to haul the products, and mitigate risks in their supply chain.

How to Choose your Potential 4PL Partner

Selecting a 4PL partner is a big decision, with wide-ranging benefits for shippers. In addition to contractual terms, pricing and other fundamental considerations, here are some other factors shippers should consider when selecting a 4PL partner:

Industry Expertise

Look for partners that have a proven track record of expertise and customer success. Ask for customer references, case studies, industry awards and recognition and other proof points. Look for examples of thought leadership, including articles, participation in industry panel discussions and other demonstrations of expertise.

Network and Capabilities

Ensure that the potential 4PL partner’s network and capabilities adequately cover your existing needs as well as your anticipated future needs.

Technology

Look for best-in-class logistics technology, including a robust and scalable TMS and integration middleware that can connect your disparate systems and deliver data and reporting. Look for a provider that has demonstrated success in creating customized solutions.

Training

Working with a new 4PL partner will include new technology. The ideal partner will offer extensive training and support for your team members to ensure they are comfortable utilizing the new systems.

Customer Service

Your 4PL is a long-term partner. Ask the 4PL to identify the specific individual team members that will be assigned to your business and require the 4PL to articulate their roles and responsibilities.

Performance Measurement

Define specific KPIs that you will use to measure and manage the performance of the 4PL and the performance of your supply chain.

Financial Stability

Review the potential 4PLs financial performance to ensure you are selecting a stable long-term partner that you have confidence in for the long haul.

Sustainability

Increasing consumer expectations and regulations are creating new challenges for shippers. Partner with a 4PL that can help support your sustainability initiatives and goals, including capturing and reporting Scope 3 CO2e emissions.

Selecting a 4PL partner is an important decision that can have a transformative impact on your supply chain, delivering cost savings, efficiency gains, service improvements, enhanced visibility, improved business intelligence and more for shippers across a wide variety of verticals. To learn more about engaging with a 4PL, please contact Sheer Logistics today.

Whether you need full logistics management, carrier sourcing, or help with any part of the logistics process, Sheer Logistics delivers industry experts and cutting-edge technology that deliver bottom-line results.